Weydiinta Pricelist

Wixii su'aalo ah ee ku saabsan alaabtayada ama qiimaha iibiyaha, fadlan noo dhaaf emaylkaaga, waanan kula soo xiriiri doonnaa 24 saacadood gudahood.

• Sifooyinka farsamaynta ee aadka u fiican oo leh fuzz yar.

• Ku habboon resins badan.

• Ku-daadin degdeg ah oo dhammaystiran.

• Sifooyinka farsamada sare ee qaybaha ugu dambeeya.

• Iska caabin heer sare ah oo ka dhan ah miridhka kiimikada.

Raadinta qof lagu kalsoonaan karoalaab-qeybiyaha tooska ah ee fiberglass-kaRaadintaadu halkan ayay ku dhammaanaysaa!Fiberglass-ka tooska ah ee roving-kawaxaa lagu sameeyaa iyadoo la adeegsanayo tignoolajiyad casri ah iyo agab heer sare ah, taasoo dammaanad qaadaysa waxqabad sare iyo cimri dherer.Fiberglass-ka tooska ah ee roving-kaWaxaa loogu talagalay isticmaallo kala duwan waxayna leeyihiin sifooyin aad u fiican oo qoyaan ah si ay uga caawiyaan ku dahaadhida resin-ka ugu fiican si loo kordhiyo xoogga iyo adkaanta. Hadday tahay wax soo saarka isku dhafan, pultrusion, winding filament, ama codsiyo kale, annagaFiberglass-ka tooska ah ee roving-kawaa kuwo ku habboon. Nala soo xiriir maanta si aad u ogaatoFiberglass-ka tooska ah ee roving-kaoo fur kartidooda si ay u horumariyaan hababkaaga wax soo saarka.

Socod toos ahwaxaa lagu dabaqi karaa tuubooyinka, weelasha cadaadiska, shabagyada, iyo astaamaha, halka roving-yada tolmada leh ee laga soo saaray loo isticmaalo doomaha iyo haamaha kaydinta kiimikada.Fiberglass rovingwaxay ka kooban tahay noocyo kala duwan, oo ay ku jiraan roving panel,socodka buufinta,SMC roaving,socod toos ah, socodka muraayadaha c-glass, iyoFiberglass rovingjarista.

| Nooca Muraayadda | E6-fiberglass toos ah oo lagu safro | ||||||||

| Nooca Cabbirka | Silane | ||||||||

| Koodhka Cabbirka | 386T | ||||||||

| Cufnaanta Toosan(tex) | 300 | 200 400 | 200 600 | 735 900 | 1100 1200 | 2000 | 2200 | 2400 4800 | 9600 |

| Dhexroorka Fiilada (μm) | 13 | 16 | 17 | 17 | 17 | 21 | 22 | 24 | 31 |

| Cufnaanta Toosan (%) | Qoyaanka ku jira (%) | Cabbirka Waxyaabaha ku jira (%) | Xoogga Jabka (Aan/Text) ) |

| ISO 1889 | ISO3344 | ISO1887 | ISO3341 |

| ± 5 | ≤ 0.10 | 0.60 ± 0.10 | ≥0.40 (≤2400 tex) ≥0.35 (2401~4800 tex) ≥0.30 (>4800 tex) |

| Sifooyinka Farsamada | Cutubka | Qiimaha | Resin | Habka |

| Xoogga Tijaabada | MPA | 2660 | UP | ASTM D2343 |

| Modulus-ka la jiido | MPA | 80218 | UP | ASTM D2343 |

| Xoogga xiirashada | MPA | 2580 | EP | ASTM D2343 |

| Modulus-ka la jiido | MPA | 80124 | EP | ASTM D2343 |

| Xoogga xiirashada | MPA | 68 | EP | ASTM D2344 |

| Haynta xoogga xiirashada (karitaanka 72 saacadood) | % | 94 | EP | / |

Xusuusin:Xogta kor ku xusan waa qiimayaal tijaabo ah oo dhab ah oo loogu talagalay E6DR24-2400-386H waana tixraac kaliya

| Dhererka baakadka mm (in) | 255(10) | 255(10) |

| Dhexroorka gudaha ee baakadka mm (in) | 160 (6.3) | 160 (6.3) |

| Dhexroorka baakidhka ee dibadda mm (in) | 280(1)1) | 310 (12.2) |

| Miisaanka baakadka kg (lb) | 15.6 (34.4) | 22 (48.5) |

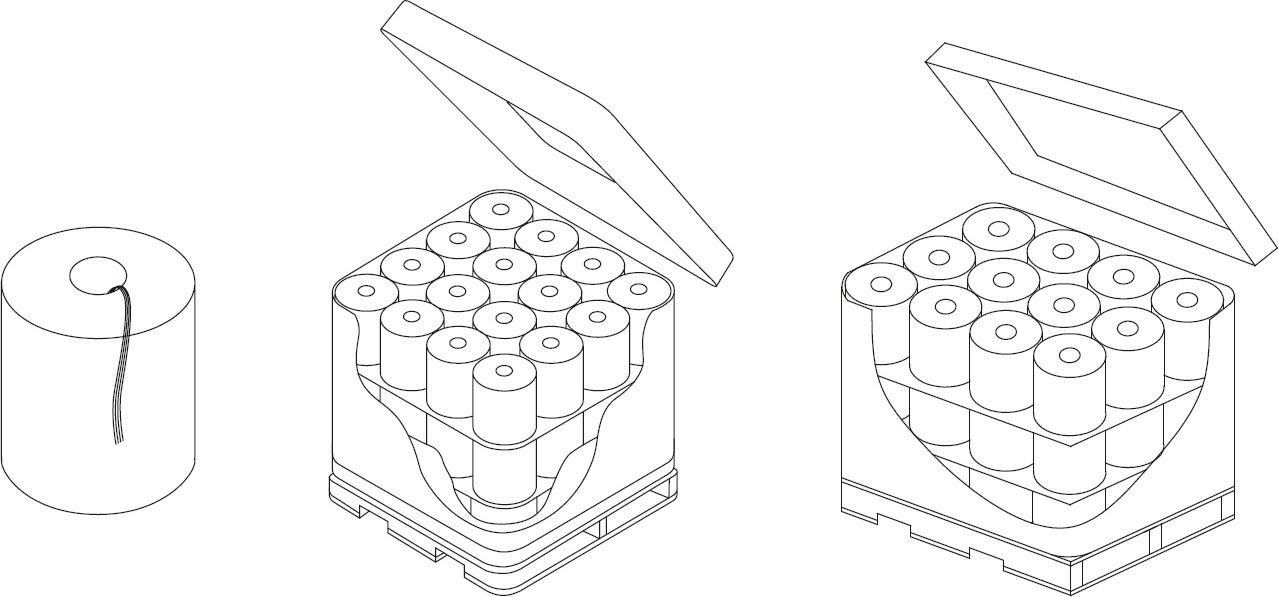

| Tirada lakabka | 3 | 4 | 3 | 4 |

| Tirada daahyada lakabkiiba | 16 | 12 | ||

| Tirada daahyada baaldi kasta | 48 | 64 | 36 | 48 |

| Miisaanka saafiga ah halkii kiilo ee baakadda (lb) | 750 (1653.5) | 1000 (2204.6) | 792 (1746.1) | 1056 (2328.1) |

| Fiberglass-ka tooska ahDhererka baaldiga mm (in) | 1120 (44.1) | 1270 (50.0) | ||

| Fiberglass-ka tooska ahBallaca baaldiga mm (in) | 1120 (44.1) | 960 (37.8) | ||

| Fiberglass-ka tooska ahDhererka baaldiga mm (in) | 940 (37.0) | 1200 (47.2) | 940 (37.0) | 1200 (47.2) |

• Haddii aan si kale loo cayimin, waxaa lagu talinayaa in alaabta fiberglass-ka lagu kaydiyo jawi qalalan, qabow, iyo qoyaan-celin leh.

• Badeecadaha galaaska ee fiberglass-ka waa in lagu hayaa baakadahooda asalka ah ilaa inta la isticmaalayo wax yar ka hor. Heerkulka qolka iyo qoyaanka waa in lagu hayaa -10℃~35℃ iyo ≤80%, siday u kala horreeyaan.

• Si looga hortago waxyeelada loona hubiyo badbaadada, iska ilaali inaad balakoonnada ku dul saarto wax ka badan saddex lakab.

• Markaad balaastikada ku dul saarayso 2 ama 3 lakab, si gaar ah u taxaddar inaad balaastikada sare si sax ah oo siman u dhaqaajiso.

Wixii su'aalo ah ee ku saabsan alaabtayada ama qiimaha iibiyaha, fadlan noo dhaaf emaylkaaga, waanan kula soo xiriiri doonnaa 24 saacadood gudahood.